Visit www.judybsails.com

Famous Hyde Quality Sail

at

Internet Prices

Visit www.judybsails.com |

March

2005 - Atomic 4 Electrical & Starting System Repairs and Maintenance

March

2005 - Atomic 4 Electrical & Starting System Repairs and Maintenance

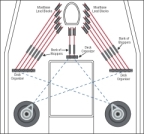

March 2005. Self Tacking Jibs - as seen at the Stockton Sailing Club.We were the guests of Bob and Arleen Campbell aboard their 1977 Tall

Rig Catalina 27. They've been sailing with babies for almost three years

now. They say that the most important "safety equipment" on

the boat is the parents' watchfulness. With a self-tacking jib, one of

them can sail the boat while the other pays attention to the two children,

now ages 16 months and three years old. They also say that self-tacking is almost a "must-have" for sailing in narrow channels, estuaries, and crowded harbors. Makes sense to us. Joe will be two years old this spring and requires constant attention if he's on the boat. If one of us can handle the boat single-handed, the other can keep an eye on Joe. We're planning on taking Joe out sailing with us this year, so we're looking at self-tacking setups. |

July

2004: Installed teak backing blocks under stanchions.

July

2004: Installed teak backing blocks under stanchions.

June

2004: Installing a removable outboard bracket so I could sail while I rewired

the engine.

June

2004: Installing a removable outboard bracket so I could sail while I rewired

the engine.

Moving the engine controls to a better spot

New manual bilge pump installed and plumbed thru aft locker

Glass laminate inside the side lockers reinforced.

Feb

7, 2003: Inspecting the gas tank. After 25 years, it's corroded and no longer

safe.

Feb

7, 2003: Inspecting the gas tank. After 25 years, it's corroded and no longer

safe.A month ago, the fuel filter clogged up from "dirty fuel". The fuel we bought wasn't the problem. The problem is corrosion inside the tank and the fittings. It's not safe to use it any more. We had it drained and we'll be replacing the gas tank with a new one. But first I have to remove the old tank.

For the interim, we've fitted a 6 gallon tank in the lazarette, properly secured down and with proper ventilaton in the lazarette, with chafe protection for the hoses, etc. Except for the extra weight in the stern, it's an easy way to solve the problem.

Bijous' new asymmetrical spinnaker . January 19,2003. It's a 2003 North G2, 596 sf. (Warning, lots of pics, may be a slow download)

The new dodger was installed just before New Year's

The new dodger was installed just before New Year's Here's the trailer and the new gate. I plan to take her home for a month

or two during the rainy season and work on her under cover.

Here's the trailer and the new gate. I plan to take her home for a month

or two during the rainy season and work on her under cover.

November 2002: Repairing the broken control for the Atomic 4

November 2002: Repairing the broken control for the Atomic 4

October 28: New glass to reinforce the traveller mounting area. There were

gelcoat cracks in the aft corners of the cockpit, near the traveller. I laid

in some new glass inside the lazarette to reinforce the area and prevent future

flexing.

October 28: New glass to reinforce the traveller mounting area. There were

gelcoat cracks in the aft corners of the cockpit, near the traveller. I laid

in some new glass inside the lazarette to reinforce the area and prevent future

flexing.

October 28: Finished installing the cabintop teak and hardware for the lines

running aft.

October 28: Finished installing the cabintop teak and hardware for the lines

running aft.

Sept 5: Installing the hinged mast-step

Sept 5: Installing the hinged mast-step

Sept

5: The Mast is finished : Finally, it's done.

Sept

5: The Mast is finished : Finally, it's done.  July

17: Mast Inspection and repair: What you can't see CAN hurt you.

July

17: Mast Inspection and repair: What you can't see CAN hurt you.The good news is that I decided to take a look at the mast behind the spreaders...

The bad news is that the the holes behind the new SS upgrade-brackets were elongated and only one compression posts was installed.... it was a mast failure waiting to happen...

The good news is that it can be repaired, but it ain't gonna be cheap to do it right. Svendsen's Rigging Shop is fabricating a set of plates and compression posts to repair it. It'll take a 7-10 days, and a couple of hundred bucks...

While I wait for Svens to fabricate the mast reinforcement, I'm

going to strip, repaint with LPU, and rewire the mast and install new nav lights..

I'm going to install new internal halyards, a halyard restrainer, new spinny

crane and a new pole track (if I can get the old one off!!!) ... and maybe a

hinged mast step... I start tomorrow.

I'm making progress...

This past week I started removing the old hardare. Removing the old traveller was a heck of a job -- took almost 4 hours! that sucker did NOT want to come loose. The old caulking was as hard as a rock.

Removed the old dodger. Removed and sold one set of Barlow #16 winches...

I've found buyers for all the used gear I'm selling (boom, dodger, winches, sail cover, etc ) and I've got cash in hand for the boom and one set of winches. My asking prices must be very competitive -- I sold everything within a couple of days.

My new mainsail has been delivered and I'll have a new mainsail cover in about a week. As soon as I get the rig back up and straight in about 7-10 days, I'll have the sailmaker come over to measure for the new jib and he and I can discuss where to put the inside genoa tracks...

Been busting my chops working on the boat...

July 10 - My friend Mike Westfield came over to help me replace all the AC wiring and upgrade to ABYC standards. It took both of us all day, and there was still 4 hours of work left for me to finish by myself. We ran new marine grade triplex safety wire and installed 3 new GFI recepticles. The OEM recepticles weren't GFI, the wire wasn't marine grade, and, to top it all off, they weren't connected properly. For example, there were 5 spades on each hot terminal, and two grounds were open. We installed a bus strip and -- check this out! -- we even put LABELS on the wires so it'll be possible to perform maintenance in the future. All the connections were made with Ancor heat-shrink terminals using a double clamping rachet tool (best $30 bucks I've spent so far!)

We tested the boat for ground leaks after we finished and also test the slip for ambient current. Everything is "cool" (as opposed to hot). So I'm gonna stop worrying about electrolysis (but I will keep checking the zincs regularly. --- Finally! I can use my power tools on the boat without fear of electrocuting myself!

Thanks Mike! I couldn't have done all this without your help.

The DC wiring is a mess, but other than getting the new nav lights rewired, it can wait until winter.

Iv'e got about half of the interior teak trim stripped, bleached and revarnished... 9 coats of Epiphanes and it looks gorgeous!

I pretty much completed all the engine upgrades and repairs. I installed a raw water filter, fresh water flushing system, audible oil and temp alarms, re-routed some wires, new exhaust hoses and clamps. Mike the Mechanic came by to torque the head and check my work.

I have my own ideas, but it never hurts to get some professional advice from

a rigger before I spend a fortune on hardware and drill dozens of new holes

in the deck.

June

6, 2002: "Boat Jewelry by Jerry"

June

6, 2002: "Boat Jewelry by Jerry"Fitting a new boom and gooseneck to the OEM mast requires some creative solutions. Master Machinist Jerry creates a beautiful piece of "jewelry" to solve the problem

Mike Lord did an engine alignment, tranny and throttle adjustment, safety inspection,

and gave me a list of "to-do's"... He gave the engine a clean bill

of health, and I breathed a sigh of relief.... Mike dispensed sage advice based

on his 25 years of working on Atomic 4 engines.

I

faired the bottom, keel and rudder, and prepped her for new bottom paint. I

worked like a dog for 5 hours.

I

faired the bottom, keel and rudder, and prepped her for new bottom paint. I

worked like a dog for 5 hours.

I found some defects in the glass wrapped around the keel that didn't show until I started fairing the bottom of the keel. I found a few spots where the 6 month old bottom paint was chipping off. I will repair the defects tomorrow.

The keel to hull joint is beautiful. The prior owner had the yard do a great job on it. However, the keel is a hair off centerline --maybe one degree, maybe two at most. And the keel is maybe one degree shy of perfectly vertical. It's hard to measure the vertical alighment, and the boot stripe can confuse the eye, but I think it's a little out of perfect alignment. That's not too bad for a Catalina 27, she should sail just fine, but it should be amusing to see how many people notice it when they take the helm.

I acid washed the topsides in preparation for buffing and waxing tomorrow. The gelcoat is in very good shape on the topsides. It'll look beautiful when it's done. The boot stripe could use repainting, but that'll have to wait. There are other things to do that are more important.

I ordered a new mainsail and 95% jib today. I practically got down on my knees and begged our sailmaker, Pineapple Sails of Alameda, to have at least the mainsail ready in time for our Anniversary in 5 weeks. It's just a few weeks to the Pacific Cup, and Pineapple Sails is working overtime. The folks at Pineapple haven't said "yes" yet; I'm waiting.

If Pineapple Sails can't get the mainsail done by June 20th or so, we'll have to drive to Sausalito for the weekend of our Anniversary, instead of sailing there. The mainsail is the original one from 1977, it has made two round trips to Hawaii and countless coastal and day trips, and I don't trust it -- too many years of UV damage, and the sail is much too baggy for sailing up the Slot and across Hurrican Alley in SF Bay's strong summer winds.

(click here for a copy of the survey in Adobe Acrobat format (caution, it's 1.6 MB), click here for pictures)

Peter Minkwitz, my surveyor, did a very thorough survey. He's highly respected around the boatyards in SF area. -- he used to be a foreman or manager or something at Svendsen's Boat Yard. He crawled all over the boat, crawled halfway upside down into every locker and practically dissappeared in the innards of the boat at times. He sounded every part of the hull for rot or delamination, and checked the usual suspect places with a moisture meter.

Peter found several things I missed in my pre-survey inspection, but not much more than I expected (except that the new Atomic needs alignment and the 110 wiring is not grounded or GFI'd). I was very pleased with the care he took to identify everything I need to do to make her a first class boat, from a safety and performance point of view.

Our new boat has a newly rebuilt Atomic 4 gas inboard, new standing rigging, and a completely rebuilt keel sump and new keel bolt .installed with the windowing technique, not lag bolts. The prior owner had done a huge amount of work on her in the past 3 or 4 years, but there's a lot of work left to do. Her gelcoat is in good shape. She is structurally very sound. (For drawings from the Catalina Factory of keel repairs and construction details, click here)

But she's also very tired and in need of refurbishment. She needs new sails, new deck hardware, new 12v and 110v wiring, navlights, instruments, a engine/shaft alignment, and all new hoses. The compass works, but none of the other instruments work.

There are a few priority defects that MUST be fixed immediately, before I can run the engine safely and before she goes back in the water. She needs two new seacocks. There's a short in her 110 recepticle in the galley, no ground to 110, no functional GFI - I don't dare plug it in until I get it fixed. The gas tank isn't grounded, so I don't dare put an fuel in her until I get that fixed. The engine room blower hoses are disconnected, and the exhaust hose is so weak it's bulging.

I'll have her out three or four days. I'll get these things sorted out before she goes back in the water. The yard will install the seacocks for me. I'll fair her hull, keel and rudder, put nw bottom paint on her, and buff and wax her topsides while she's on the hard. I'll ground the gas tank. I'll probably just disconnect the shore power until I have time to replace everything. I'll get the engineblower hoses connected and clamped on. I'll remove the exhaust hose and get a replacement (I can do this job after we put her back in the water.)

My buddy Jerry Barrilleaux dropped by after the survey and I showed him the boat. We had a good ole' time poking around the boat and sitting in the cockpit, with the boat 10 feet up in the air. Jerry is a high tech R&D machinist -- he builds precision scientific instruments for high tech industries. He brought his precision instruments and measured the rudder head fittings so he can maching something to get rid of the sloppy tiller.

The slop in the tiller caused by the worn holes in both the rudder head and the tiller bracket. The tiller wobbles from side to side about 4" at the forward end. During the sea-trial before buying her, the boat felt like a car with a loose steering wheel.

The tiller bracket thru-bolt has "egged out" a hole in the rudder head casting. I suspect it happened for three reasons:

1) the total bearing surfaces area was inadequate for the forces involved.

2) the tolerances on all three parts (rudder head, tiller bracket, and bolt) were probably pretty imprecise to start with. All the parts are sand castings, not machined Sloppy tolerances cause point loading at a single place inside the hole, which always leads to hole elongation of the hole, if it a load bearing part.

3) the tiller bracket bolt had threads that were wearing agaist the rudder head. Basically, the bolt was too short and the threads wore on one end of the hole drilled in the rudder head. Having threads rubbing inside a hole is a sure-fire way to elongate a hole -- if you've got a bolt like that somewhere on your boat, get a longer bolt so the threads don't wreck your gear.

Jerry measured the gooseneck components to, to 1/10,00 of an inch. I need to know the exact measurements to build a new gooseneck (or buy one) that won't "egg out" on me. If I need it, Jerry promised to machine custom stainless-steel part to make the gooseneck hurricane proof. I may just get a new boom and install all internal components, or order one from Selden (they make really NICE, but defintely not inexpensive, booms), rather than try to adapt the existing boom to my personal rigging preferences. But my budget for the recommissioning is not unlimited, and half of it is earmarked for sails, so I might have to rebuild the existing boom. We'll see what happens...

I'll be getting the written survey via fax tomorrow. The list of deficiencies will constitute half of my plan for her recommissioning. The other half will be getting new sails, re-doing all her deck hardware and the boom.

Bruce

H's 1978 Catalina 27 Hull # 3854 -

Bruce

H's 1978 Catalina 27 Hull # 3854 - Send email to: Sailing@Blumhorst.com

sailboat, boat, sail boat, sailing, sail, marine, charter, instruction, yacht, DIY, navigation, rigging, winch, rope clutch, deck organizer, halyard, jib, mainsail, furler, reefing, vang, spinnaker, outhaul, fillet, dodger, mast, boom, traveller, mainsheet, cunningham,epoxy,gelcoat,fiberglass,boat repair, boat maintenance, inboard, outboard, bottom paint, gps, compass, depth sounder,marina, boatyard, sailboat charter